ProductsElectric Wire Rope

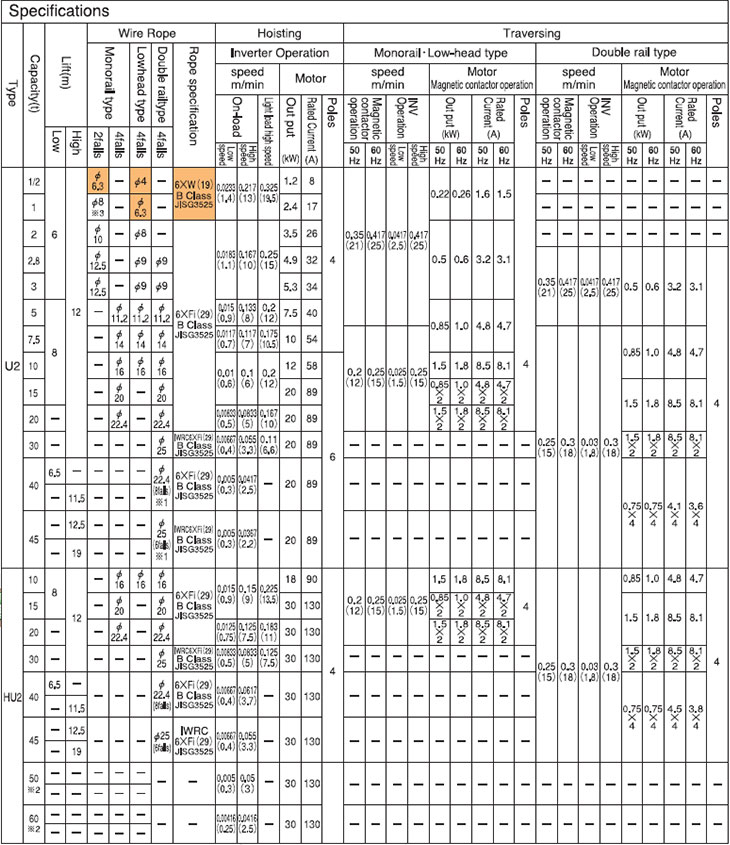

U2,HU2 Type Series Ultra type 1/2t ∼ 60t

Included over load prevention function as standard equipment

Adoption of S type body

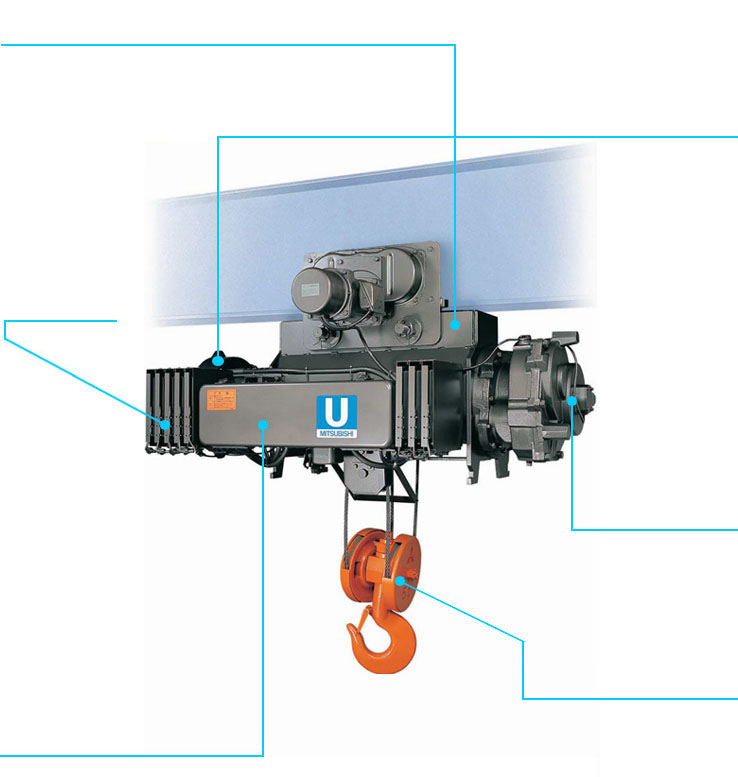

This series is based on the model S, high-performance parent body which features highest-in-class hoisting speed, power, and durability, and withstands repeated operations.Resistance unit

- Cement resistances are

unitized for downsizing.

(For hoist rated for 10 ton or less) - Adoption of the connector

system facilitates hoist work.

(For hoists rated for 10 ton or less)

Control panel integrating purpose-built inverter

- The control panel, made compact with an integrated inverter only for hoist, has improved environmental resistance.

- Simple parameter setting operation

*Allows operating speed to be specified freely

*Allows selection of light-load high-speed function.

*Allows the position detection point to be specified freely. - Troubleshooting facilitated by abnormality display.

Low-wearing electromagnet brake

- Heat-generation and wear are small under severe inching operations accompanied by braking operations at low motor-speeds in the inverter-driven power train. (However, frequent use of the unloaded high-speed function may result in increased brake disk wear.)

- Hoists rated for 7.5 ton or more are equipped with an emergency brake.

Rotating sensor

- Full-time monitoring of hoist motor motion; detects abnormalities and stops the machine if necessary as a safety precaution.

- Detects position using rotation pulses; reduces machine speed when approaching the upper or the lower limit and stops it there.

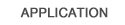

- Detects light-load and automatically operates light-load high-speed.

Smooth operation

- Infinitesimal and light-moving inching operations

- Smooth changeover between high-and low-speed operations

Introduction of UA type 45 kW series |

||||||||||||||||||||||||

• 45 kW hoisting motor has further improved machine speed |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

* Outside dimensions of this hoist differ from those listed on this catalog; contact us for further information. * A general-purpose inverter will be installed. * Some functions of this hoist differ from those on other Soukai-TEI products. |

||||||||||||||||||||||||

Manufacturing specifications for typical large-capacity hoists |

|||||||||||||||||

|

|||||||||||||||||

* 400 V series are also available; contact us for further information.

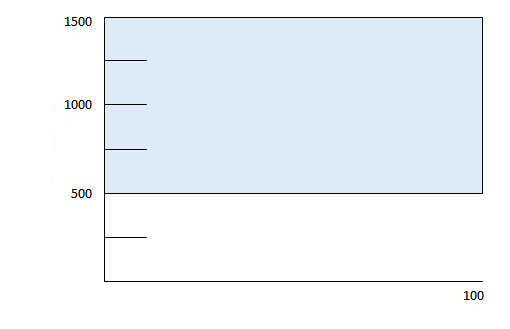

Note: AC Reactor

The inverter hoist might be damaged when it is connected directly with the large capacity power transformer (more than 500kVA transformer), there is a switch of the phase advance capacitor and the excessive peak current inflows into the power supply input circuit. In such caces, please make sure that the AC reactor is installed on the primary side of the inverter hoist.Power supply

equipment

capacity (kVA)

Inverter hoist that develops new use and new field

1 Please note that 40t is 8falls and 45t is 6falls. (Please contact us for 60t separately.)

2 Please contact us for 50t and 60t separately

3 Rope specification of 1t 2falls is 6 X Fi (29)

Standard Specifications

- Power supply

- *** 3-phase 200V 50/60Hz control 200V,220V 60Hz control 220V (400Vclass is also available)

- *** 3-phase 400V 50/60Hz control 200V, 440V 60Hz control 220V

- *** 3-phase 380V 50Hz control 48V(100V and 24V are also available)

- Operating method Push button switch operation.

* Above push buttons are all 2 step push buttons excluding "ON" and "OFF"

1/2t ∼ 3t

5t ∼ 45t

Suspended type

Frame mounted type2 Points

4 Points

U D

ON OFF U D

Motor operated traversing hoist

6 Points

8 Points

U D E W S N

ON OFF U D E W S N

- Rating

Hosting (less than 5t) 40%ED (63% of load rating). 400S/Hr

(More than 7.5t) 25%ED (63% of load rating). 150S/Hr JIS C 9620 - Power supply system

***Cable feeding, trolley feeding(only double trolly) - Ambient air temperature

*** -10°C to 40°C (Non congelation) - Ambient air humidity

***90% or less (Non condensing) - Enclosure

***Simplified out door type (JIS C 0920. Equivalent to IP-44) - Please prepare the shelter place or the instlation of rain cover when it is used in outdoor.

- Applicable standard

***JIS C 9620 electric hoist/crane structure standard. - Color coating

***Main body: Metallic gray (Equivalent to Munsell N4.0)

Hook block: Munsell7.5YR7/14

Pushbutton: Equivalent to Munsell7.5YR7/13

U2 • HU2 Type (200V/400 class)

|

|||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|