|

STATE-OF-

THE-ART

TECHNOLOGY,

ADAPTED TO

THE CUSTOMER'S

NEEDS |

|

|

Load control

|

Hoist versions |

|

All our hoists come equipped with the model ALE-100/TN electronic limiter, with record and control function. Designed for overload, loose wire rope and motor overheating control. also records the load spectrum of the hoist as per UNE 58919 standard.

In combination with the overload cell, it enables optional viewing of hanged load and Safe Operating Period control::

- Number of lifting manoeuvres.

- Number of inching manoeuvres.

- Lifting manoeuvre time.

- Number of overloads.

- Number of trolley manoeuvres.

- Number of bridge manoeuvres.

- Activation of next inspection alert by number of hours and/or date.

This data can be viewed on the remote control. |

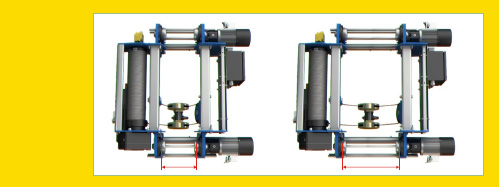

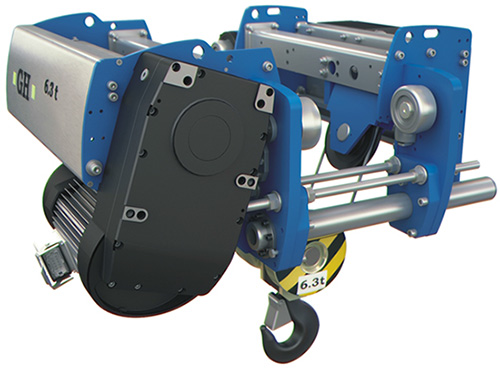

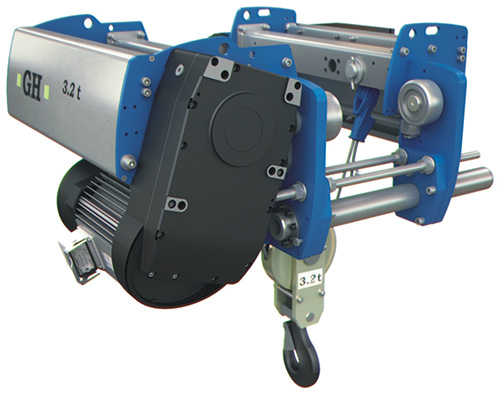

We adapt the features of our products to meet our customers' needs.

- Hoist for curves.

- Cradled double-girder trolley.

- Hoist with console trolley.

- Motorised rotary trolley.

- Dual hoist double-girder trolley.

- Dual hook double-girder trolley.

- Trolley with hoist parallel to end carriages.

- Double-girder tube trolley with platform.

- Winder trolley.

- Hoist between girders.

- Recess-mounted double-girder trolley with 2 cable exits and rack conveying. |

Other options

- Anti- collision photocells.

- Weighing display.

- Safety brake on drum.

- Hook blocking system.

- Remote control.

- Data displayed on remote control.

- Data displayed on radio remote control. |

|

| |

|

Frequency inverter for hoist and cross travel motions

|

|

|

| Electronic load limit device (ALE-100/TN) |

Radio remote control with display (on the radio) |

|

|

|

A WIDE

RANGE IS

AVAILABLE |

|

|

Standard: Frequency inverter on hoisting

Models GHA12, GHB11 and GHD12

- Nominal speed at full load

|

5m/min. |

| - Overspeed at 1/4 load |

8m/min. |

Optional: 2-speed motor

Hoisting speed

- 5/0.8 m/min. GHB11, GHD12

Hoisting speed

- 5/1.25 m/min. GHA12

Other options available. |

|

| A11 |

|

R |

|

06 |

|

41 |

|

04 |

|

H2 |

|

M5 |

| |

|

|

|

|

|

|

|

|

|

|

|

FEM duty (M5 - M8) |

| |

|

|

|

|

Lifting height (H1 - H5) |

| |

|

|

|

Lifting speed (4 m/min = 04) |

| |

|

|

Reeving arrangement (2/1, 4/1, 4/2, etc.) |

| |

|

Hoist capacity (e.g. 3.2 t = 03; 10 t = 10) |

| |

Hoist type. Execution (M: Single girder normal headroom, R: Single girder low headroom; B: Double girder with tubes; F: Fixed; T: with end carriages) |

| Hoist type. Size (A, B, D). Version. |

|

| |

KG. |

HOIST |

SPEED

M/MIN

|

FALLS |

DUTY

FEM |

HOL (HEIGHT OF LIFT) (M) |

H1 |

H2 |

H3 |

H4 |

1,000 |

GHA12_014105M7 |

5 |

4/1 |

M7 |

4.5 |

8 |

10.8 |

|

GHA12_012110M6 |

10 |

2/1 |

M6 |

9 |

16 |

21.6 |

|

GHB11_011116M7 |

16 |

1/1 |

M7 |

14.5 |

27.1 |

37.2 |

47.3 |

GHB11_012216M7 |

16 |

2/2 |

M7 |

4 |

10.3 |

15.4 |

20.5 |

GHB11_011120M6 |

20 |

1/1 |

M6 |

14.5 |

27.1 |

37.2 |

47.3 |

GHB11_012220M6 |

20 |

2/2 |

M6 |

4 |

10.3 |

15.4 |

20.5 |

GHD12_012220M7 |

20 |

2/2 |

M7 |

4.9 |

14.4 |

29.5 |

37 |

GHD12_011120M7 |

20 |

1/1 |

M7 |

15.2 |

28.8 |

51 |

61.9 |

1,600 |

GHA12_014105M7 |

5 |

4/1 |

M7 |

4.5 |

8 |

10.8 |

|

GHA12_012110M5 |

10 |

2/1 |

M5 |

9 |

16 |

21.6 |

|

GHB11_012216M5 |

16 |

2/2 |

M5 |

4 |

10.3 |

15.4 |

20.5 |

GHB11_011116M5 |

16 |

1/1 |

M5 |

14.5 |

27.1 |

37.2 |

47.3 |

GHD12_012220M7 |

20 |

2/2 |

M7 |

4.9 |

14.4 |

29.5 |

37 |

GHD12_011120M7 |

20 |

1/1 |

M7 |

15.2 |

28.8 |

51 |

61.9 |

2,000 |

GHA12_024105M7 |

5 |

4/1 |

M7 |

4.5 |

8 |

10.8 |

|

GHB11_022108M7 |

8 |

2/1 |

M7 |

7.26 |

13.55 |

18.6 |

23.6 |

GHB11_024208M7 |

8 |

4/2 |

M7 |

|

5 |

7.5 |

10 |

GHB11_022110M6 |

10 |

2/1 |

M6 |

7.26 |

13.55 |

18.6 |

23.6 |

GHB11_024210M6 |

10 |

4/2 |

M6 |

|

5 |

7.5 |

10 |

GHD12_022216M7 |

16 |

2/2 |

M7 |

4.9 |

14.4 |

29.5 |

37 |

GHD12_021116M7 |

16 |

1/1 |

M7 |

15.2 |

28.8 |

51 |

61.9 |

GHD12_022220M6 |

20 |

2/2 |

M6 |

4.9 |

14.4 |

29.5 |

37 |

GHD12_021120M6 |

20 |

1/1 |

M6 |

15.2 |

28.8 |

51 |

61.9 |

2,500 |

GHA12_024105M6 |

5 |

4/1 |

M6 |

4.5 |

8 |

10.8 |

|

GHB11_022108M6 |

8 |

2/1 |

M6 |

7.26 |

13.55 |

18.6 |

23.6 |

GHB11_024208M6 |

8 |

4/2 |

M6 |

|

5 |

7.5 |

10 |

GHB11_022110M5 |

10 |

2/1 |

M5 |

7.26 |

13.55 |

18.6 |

23.6 |

GHB11_024210M5 |

10 |

4/2 |

M5 |

|

5 |

7.5 |

10 |

GHD12_022216M6 |

16 |

2/2 |

M6 |

4.9 |

14.4 |

29.5 |

37 |

GHD12_021116M6 |

16 |

1/1 |

M6 |

15.2 |

28.8 |

51 |

61.9 |

GHD12_022220M5 |

20 |

2/2 |

M5 |

4.9 |

14.4 |

29.5 |

37 |

GHD12_021120M5 |

20 |

1/1 |

M5 |

15.2 |

28.8 |

51 |

61.9 |

|

| |

KG. |

HOIST |

SPEED

M/MIN |

FALLS |

DUTY

FEM |

HOL (HEIGHT OF LIFT) (M) |

H1 |

H2 |

H3 |

H4 |

3,200 |

GHA12_034105M5 |

5 |

4/1 |

M5 |

4.5 |

8 |

10.8 |

|

GHB11_034105M7 |

5 |

4/1 |

M7 |

3.6 |

6.8 |

|

10 |

GHB11_032108M5 |

8 |

2/1 |

M5 |

7.26 |

13.55 |

18.6 |

23.6 |

GHB11_034208M5 |

8 |

4/2 |

M5 |

|

5 |

7.5 |

10 |

GHB11_034208M7 |

8 |

4/2 |

M7 |

|

7 |

|

18.5 |

GHD12_032110M7 |

10 |

2/1 |

M7 |

7.6 |

14.4 |

25.5 |

31.0 |

GHD12_034210M7 |

10 |

4/2 |

M7 |

|

7 |

14.7 |

18.5 |

GHD12_032216M5 |

16 |

2/2 |

M5 |

4.9 |

14.4 |

29.5 |

37 |

GHD12_032116M5 |

16 |

1/1 |

M5 |

15.2 |

28.8 |

51 |

61.9 |

4,000 |

GHB11_044104M7 |

4 |

4/1 |

M7 |

3.6 |

6.8 |

|

10 |

GHB11_044105M6 |

5 |

4/1 |

M6 |

3.6 |

6.8 |

|

10 |

GHD12_042108M7 |

8 |

2/1 |

M7 |

7.6 |

14.4 |

25.5 |

31 |

GHD12_044208M6 |

8 |

4/2 |

M7 |

|

7 |

14.7 |

18.5 |

GHD12_042110M6 |

10 |

2/1 |

M6 |

7.6 |

14.4 |

25.5 |

31 |

GHD12_044210M6 |

10 |

4/2 |

M6 |

|

7 |

14.7 |

18.5 |

5,000 |

GHB11_054104M6 |

4 |

4/1 |

M6 |

3.6 |

6.8 |

|

10 |

GHB11_054105M5 |

5 |

4/1 |

M5 |

3.6 |

6.8 |

|

10 |

GHD12_052108M6 |

8 |

2/1 |

M6 |

3.6 |

14.4 |

25.5 |

31 |

GHD12_054208M6 |

8 |

4/2 |

M6 |

7.6 |

7 |

14.7 |

18.5 |

GHD12_052110M5 |

10 |

2/1 |

M5 |

|

14.4 |

25.5 |

31 |

GHD12_054210M5 |

10 |

4/2 |

M5 |

7.6 |

7 |

14.7 |

18.5 |

6,300 |

GHB11_064104M5 |

4 |

4/1 |

M5 |

3.6 |

6.8 |

|

10 |

GHD12_064105M7 |

5 |

4/1 |

M7 |

3.8 |

7.2 |

10 |

12.8 |

GHD12_062108M5 |

8 |

2/1 |

M5 |

7.6 |

14.4 |

25.5 |

31 |

GHD12_064208M5 |

8 |

4/2 |

M5 |

|

7 |

14.7 |

18.5 |

8,000 |

GHD12_084104M7 |

4 |

4/1 |

M7 |

3.8 |

7.2 |

10 |

12.8 |

GHD12_084105M6 |

5 |

4/1 |

M6 |

3.8 |

7.2 |

10 |

12.8 |

10,000 |

GHD12_104104M6 |

4 |

4/1 |

M6 |

3.8 |

7.2 |

10 |

12.8 |

GHD12_104105M5 |

5 |

4/1 |

M5 |

3.8 |

7.2 |

10 |

12.8 |

12,500 |

GHD12_124104M5 |

4 |

4/1 |

M5 |

3.8 |

7.2 |

10 |

12.8 |

|

2/1 reeving configuration

2/1 reeving configuration